Strona główna / Services

Discover our services - serial and mass production.

Our services include mass production of small, medium, and large plastic products. Choose the service that suits your needs, and our engineers will advise you on which materials and technologies will work best for your product.

Comprehensive and efficient production of plastic products.

The first step in the serial production process is to design the product, followed by its modification until the final model is achieved, which meets all your needs. We will help you choose the best plastic material for your product.

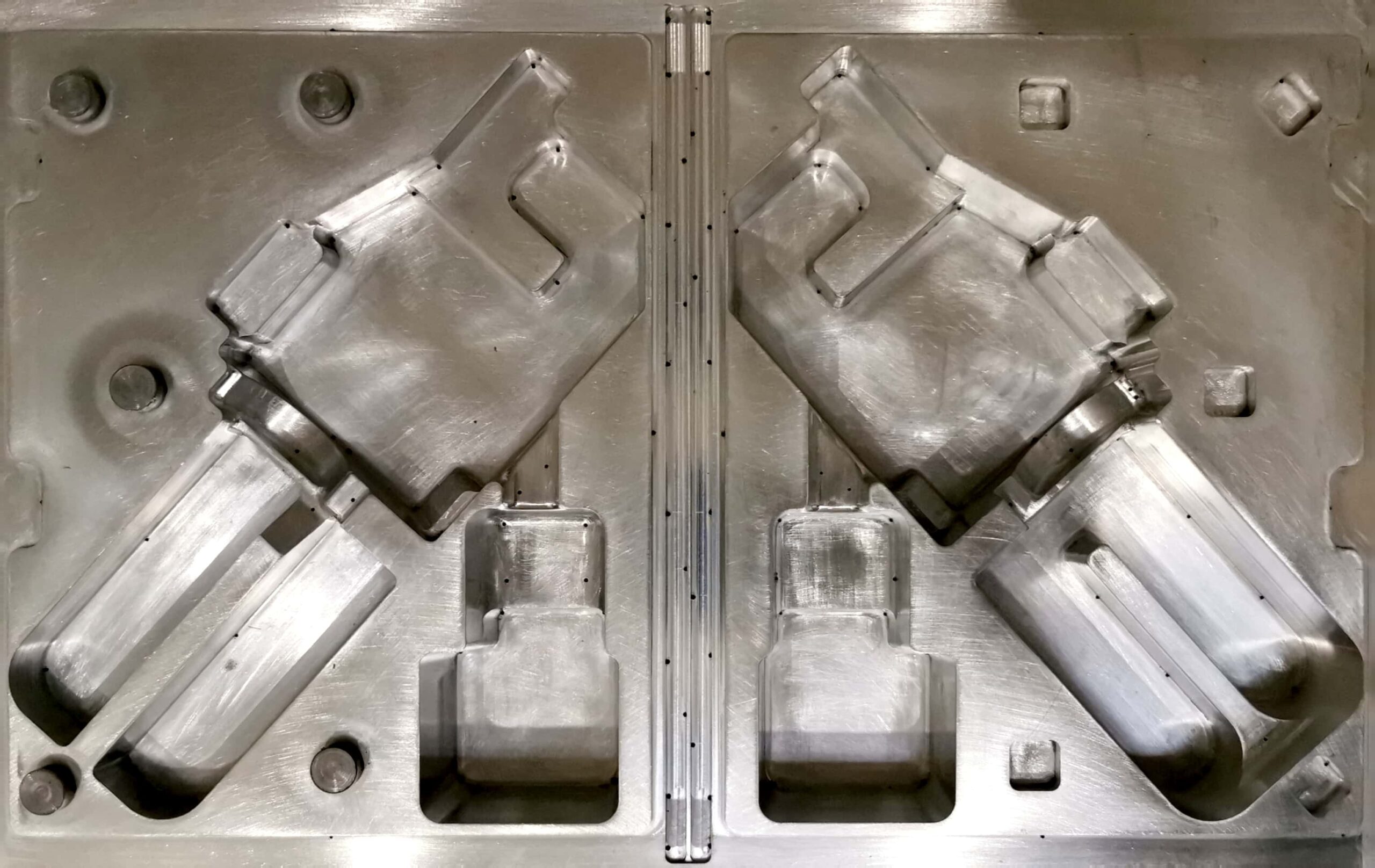

The next step will be designing and manufacturing the mold according to the chosen production technology. We will test the mold for durability, and then create a product prototype. Only after your approval, we will commence large-scale production of the product.

Mass production, serial production, or prototyping? With us, you can be sure that we will carry out production series using the optimal processing technology.

We will determine how to produce production series in order to minimize waste, reduce costs, and avoid incorrectly made production series.

We design and manufacture molds for mass production of products in technologies such as rotational molding, thermoforming, injection molding, and extrusion.

We create large plastic products for every industry where precision, durability, and cost optimization are essential.

What materials do we use in plastic production?

For production, we can use any plastic materials available on the market. Some examples of plastics we use include polyethylene, polypropylene, polyvinyl chloride, polystyrene, and ABS. Depending on the technology, the input material can take the form of sheets, foil, granules, powder, or filament.

We specialize in large production series

From the smallest products to large-scale items, thanks to

our comprehensive services, we can fulfill any large

order for the production of plastic products.

Every time, we make an effort to reduce production costs while maintaining all the necessary product parameters.

- you need cyclical production of plastic products (according to monthly or yearly demand)

- you want to produce small products or large-scale items

- you are interested in producing a production series based on a conceptual design or existing technical documentation (drawings, 3D models)

- you need products that are readily available on the market (e.g., in catalogs or stores), such as bottles, containers, or food storage containers

- you want to produce a one-time production series

- you need a small production series.

FAQ

Check the answers to frequently asked questions

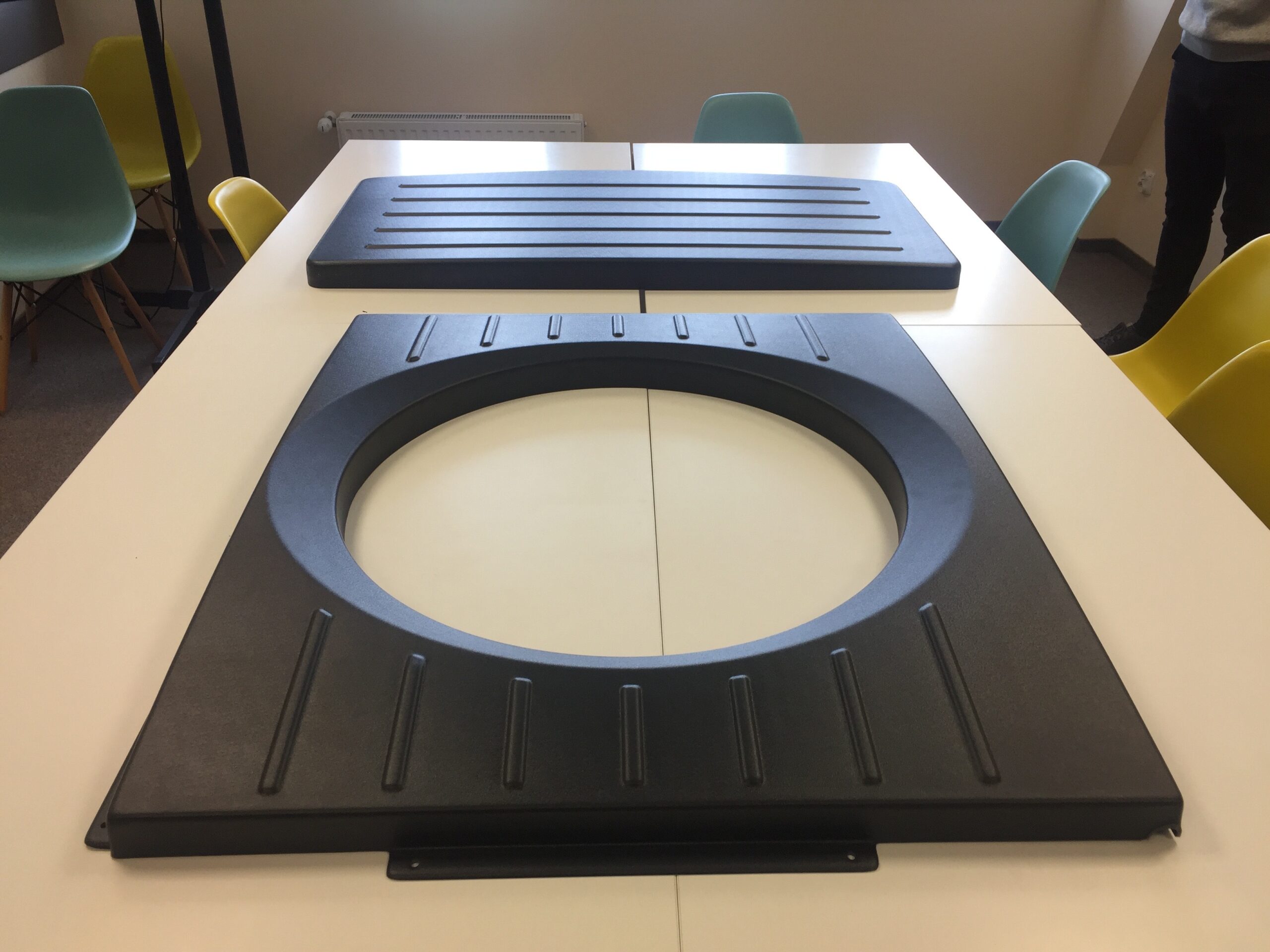

We produce various plastic products, ranging from small components to large ones. Due to our wide technological capabilities, we collaborate with various industries. Some examples of our work include machine and equipment parts, casings, covers, shields, manholes, profiles, tanks, and more.

We produce various plastic products, ranging from small components to large ones. Due to our wide technological capabilities, we collaborate with various industries. Some examples of our work include machine and equipment parts, casings, covers, shields, manholes, profiles, tanks, and more.

At each stage, we help tailor the project to a dedicated technology. We assist in understanding the essential aspects of the production process, the course of serial production, and present several concepts for implementing the project. Consulting services are an integral part of our collaboration and are provided at no additional cost.

The manufacturing of a mold is necessary for technologies dedicated to serial and mass production, such as injection molding, thermoforming, rotational molding, and extrusion.

Types of serial production are determined based on how many products are manufactured in one production cycle. Both serial production, medium-scale production, and large-scale production enable efficient production of a large number of similar products. The characteristic feature of these production methods is that all products are produced in the same way. In the case of serial production, the mold is first created, which results in a low unit production cost. After creating the mold, the prototype is produced and accepted, and then production batches are produced according to the schedule. Serial production stands out with lower production costs per unit and allows for the production of a larger number of products in a shorter time, which is crucial in industries requiring high efficiency. Serial production is primarily used in the automotive, electronics, and household appliances industries.

On the other hand, small-batch production (also known as low-volume or custom production) is associated with significantly higher costs per individual product. This is because in custom production, the initial setup cost in the form of a mold is spread over a smaller number of products, or the mold is not produced at all, making production less efficient. Small-batch production, although it offers greater flexibility and the ability to tailor to specific needs, comes with much higher unit costs. The absence of a mold and the smaller production scale limit efficiency and increase the manufacturing costs for small quantities of products, which is characteristic of non-standard or specialized production.

High-volume production has many advantages. Firstly, it allows for a reduction in the production costs of plastic parts because products are manufactured in batches, which translates to a shorter setup time and lower costs for configuring machines. Additionally, mass production ensures a very high level of precision in products if the production technology is properly matched to the type of product. Most of the production process is stabilized, meaning that there are no deviations in production efficiency and product quality. What are the disadvantages of mass production? The drawbacks include relatively high initial costs, which are the costs of tooling.

Do you want to estimate the serial production of plastic products? Get a quick response from our engineers by asking about serial production in the contact form.

Our production processes are designed to provide our customers with as fast lead times as possible and avoid production delays. The lead time depends on various factors, including the size of the production run and the complexity of the ordered products.

Are you interested in serial production of plastic parts? Get a quick estimate of lead times by filling out our contact form.

In the manufacturing industry, to assess profitability, it is necessary to estimate the cost of the product, which is the sum of the production cost and the depreciation of the mold. Mold depreciation is the cost divided by the number of products manufactured. If the cost of the product is lower than alternative solutions, it means that serial production is profitable.