Strona główna / Technologies / Extrusion of plastics

Extrusion of plastics

The ideal technology for large production runs of long components such as profiles, pipes, or seals.

What is plastic extrusion?

Plastic extrusion is a manufacturing process for producing long items from plastics. During extrusion, the fluid plastic material is pushed through a channel of the desired profile in the plasticizing system of the extruder. Under pressure, the material is shaped in the head and passes through a calibrator. After cooling, the extruded product is cut to size or wound on a drum. The items are most commonly made from thermoplastics and vulcanizing elastomers. This technology is ideal for large series and mass production, where the products made are of larger or more complex sizes.

What are some typical applications of plastic extrusion?

Profiles

Bottles

Pipes

Gutters

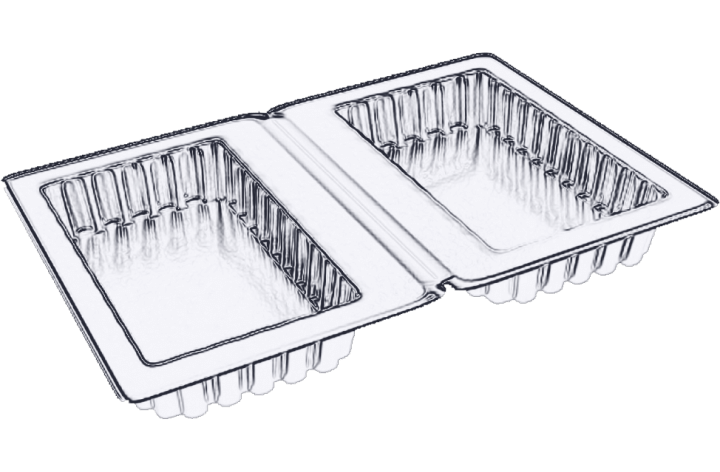

Packaging

Window frames

Foils

Thermoplastic coatings

...and many more!

Wire insulation

Plastic sheets

How does the plastic extrusion process work?

Input of material

The plastic extrusion process begins by feeding polymer material from a hopper into the extruder's barrel, which softens the material. In plastic extrusion, the raw composite material is typically in the form of granules that are gravity fed from the upper hopper into the extruder barrel. Thorough mixing of the ingredients is crucial.

Material melting

The material (along with various auxiliary components) is melted to achieve a uniform mass and appropriate temperature through mechanical energy generated by rotating screws and heaters distributed along the barrel. This occurs in the plasticizing system, leading to the homogenization of the material.

Extrusion of plastic

The molten polymer from the heated cylinder zone (having the desired consistency of the material) is then injected into a die that shapes it while it hardens during cooling to the desired dimensions.

What materials are used in plastic extrusion?

Materials in the form of granules used in plastic extrusion include, among others, polyethylene (PE), polypropylene, acetal, acrylic, nylon (polyamides), polystyrene, polyvinyl chloride (PVC), acrylonitrile-butadiene-styrene (ABS), and polycarbonate. During extrusion, the process parameters are crucial and depend on the nature of the processed material.

What are the advantages of plastic extrusion?

you obtain a finished product ready for use, virtually without finishing processing

high quality and repeatability of shape and dimensions, product aesthetics

the possibility of full automation and computerization of the process

the ability for mass production

low labor intensity

low emission of harmful substances.

We use 4 production technologies

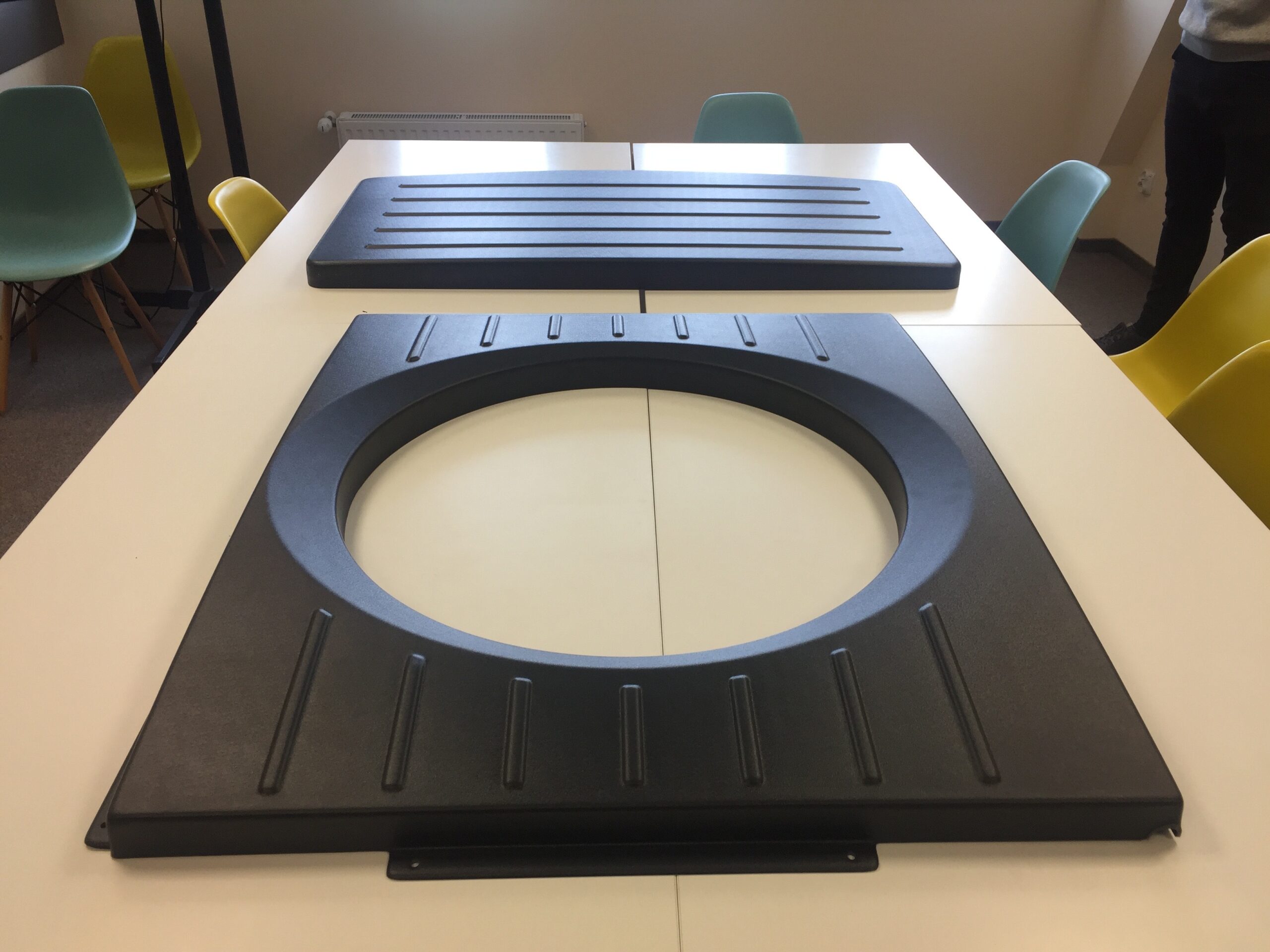

Thermoforming

Technology to reduce the time it takes to manufacture plastic products and reduce tooling costs.

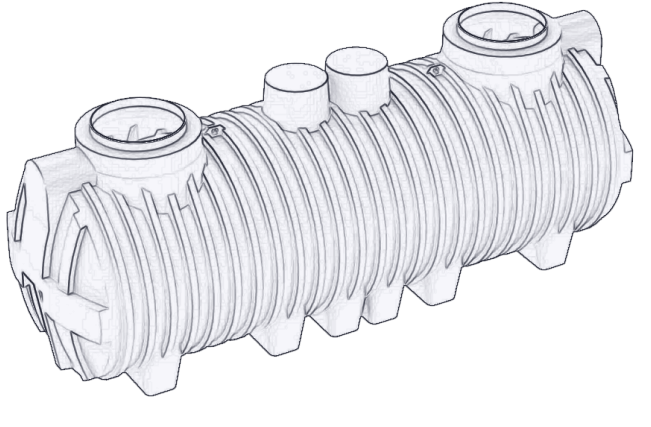

Rotational moulding

Ideal technology for manufacturing large-scale plastic products.

Example application:

- containers for fuel or chemicals

- industrial tanks

- containers for food or water

- canoes and boats

- safety helmets

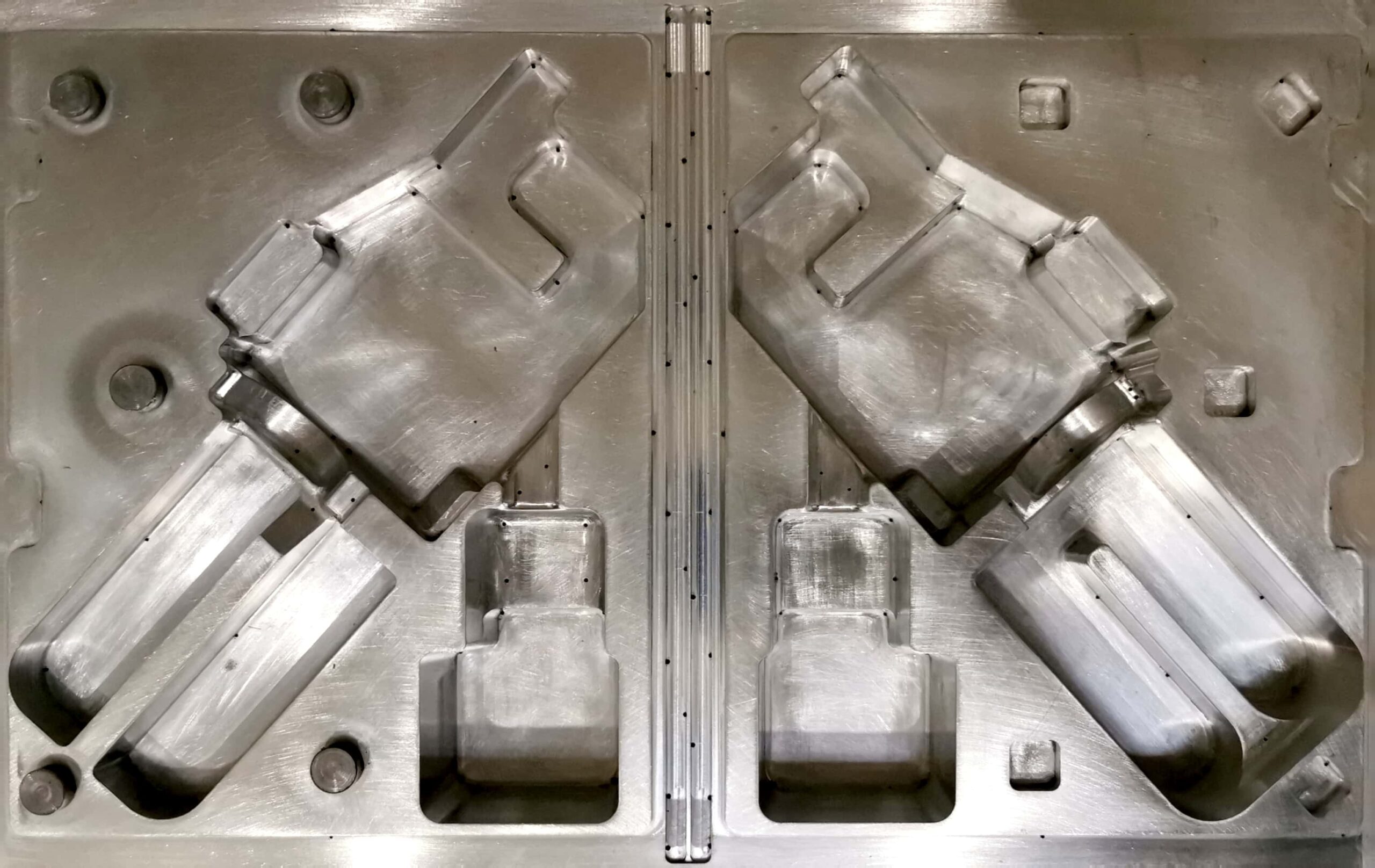

Injection molding

One of the most efficient and most widely used methods of producing simple as well as complex plastic products.

Example application:

- components of household appliances and consumer electronics

- enclosures

- bottle caps

- everyday use items

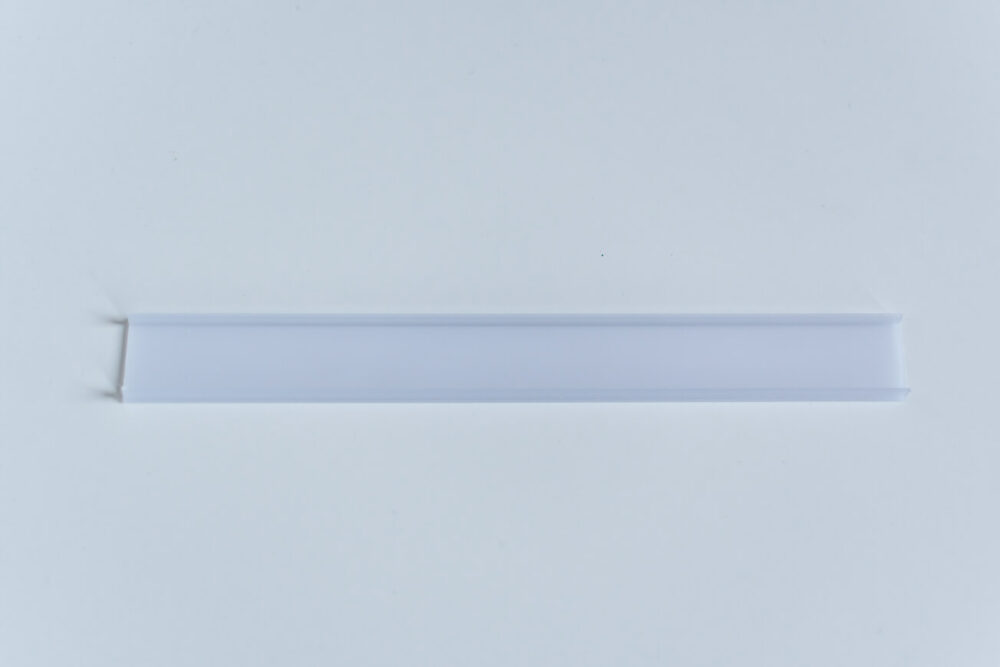

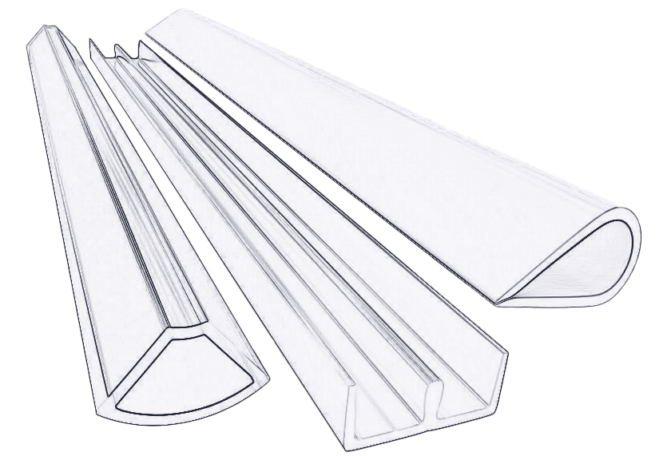

Extrusion

Ideal technology for large production runs of long components, such as profiles, pipes or gaskets.

Frequently Asked Questions

Extrusion is the ideal technology for producing elements with a constant cross-section, including:

- profiles

- pipes

- seals

- window frames

- banner elements

The cost of a mold typically ranges from several thousand to several tens of thousands of PLN.

The extrusion process consists of 3 stages:

- Input of material – The plastic extrusion process begins with the introduction of material in the form of granules.

- Material Melting – The material is then melted, and it is crucial to achieve a uniform mass and the right temperature.

- Material Extrusion – The molten polymer is then extruded into a die that shapes it while it hardens during cooling to the desired dimensions.