Strona główna / Technologies

Learn about our technologies

production

We offer as many as 4 production technologies which enables us to offer

Our customers optimal solutions for plastic manufacturing

artificial.

Wide range of production capabilities

Thanks to our extensive technological capabilities, depending on the

from the need and application, we can realize almost any

plastic project in any quantity.

We use as many as 4 manufacturing technologies for this – injection molding, extrusion, rotary casting and thermoforming.

We use 4 production technologies

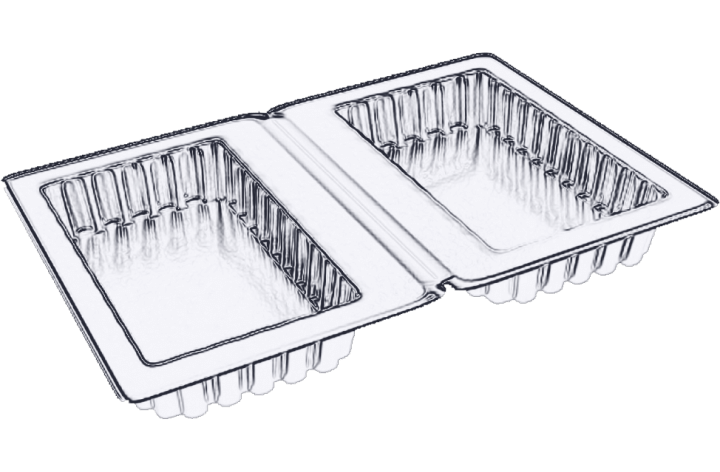

Thermoforming

Technology to reduce the time it takes to manufacture plastic products and reduce tooling costs.

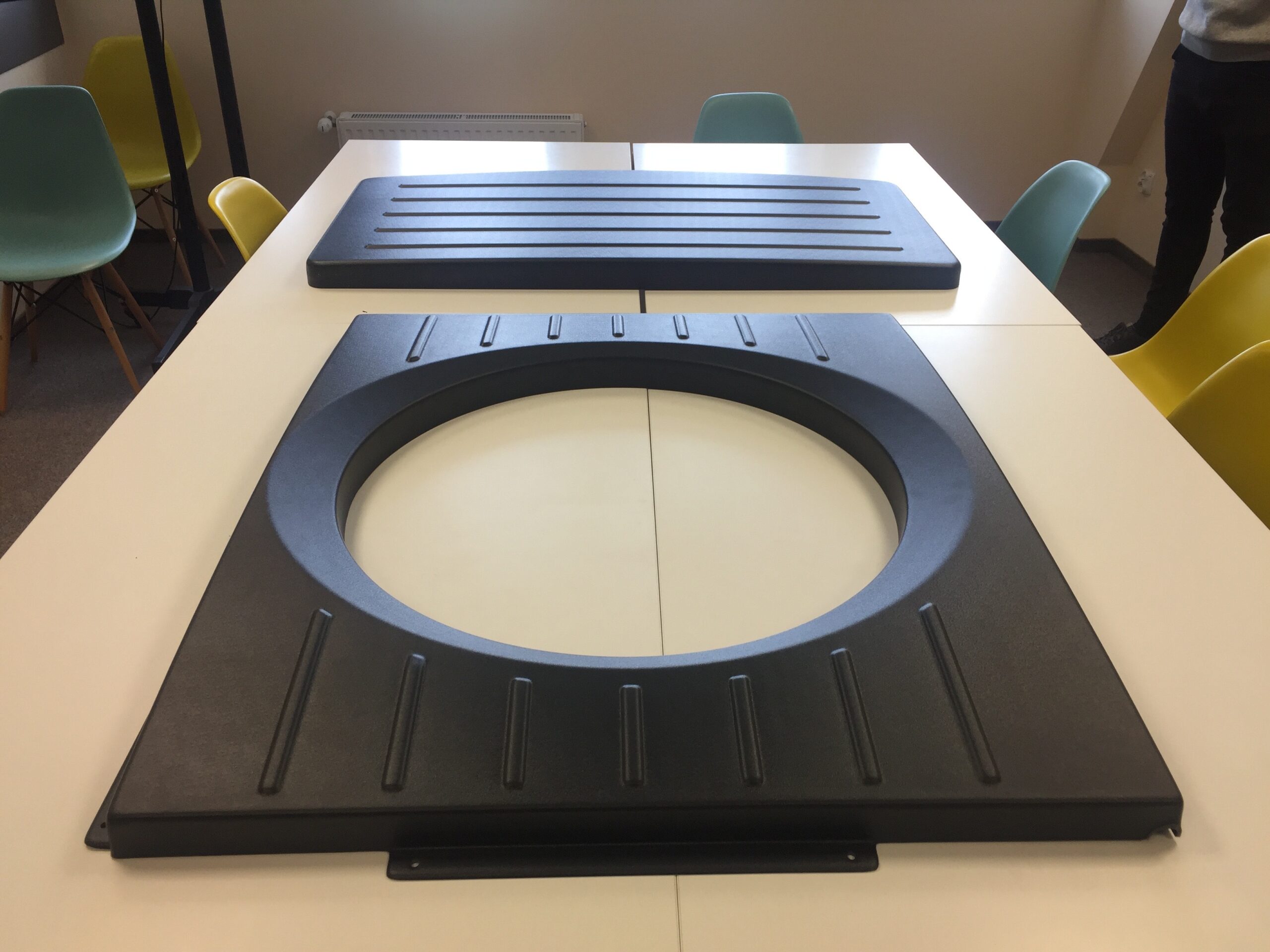

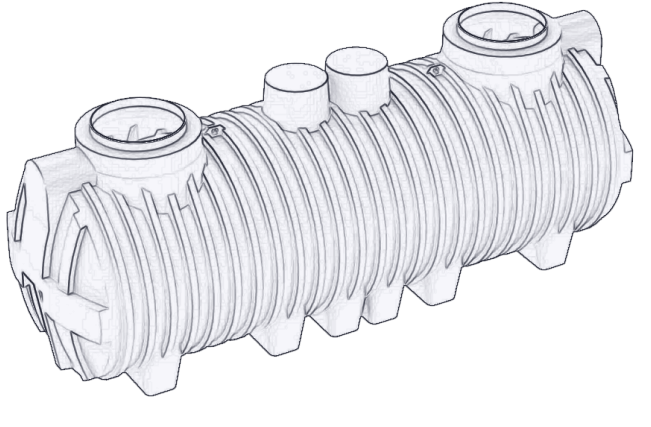

Rotational moulding

Ideal technology for manufacturing large-scale plastic products.

Example application:

- containers for fuel or chemicals

- industrial tanks

- containers for food or water

- canoes and boats

- safety helmets

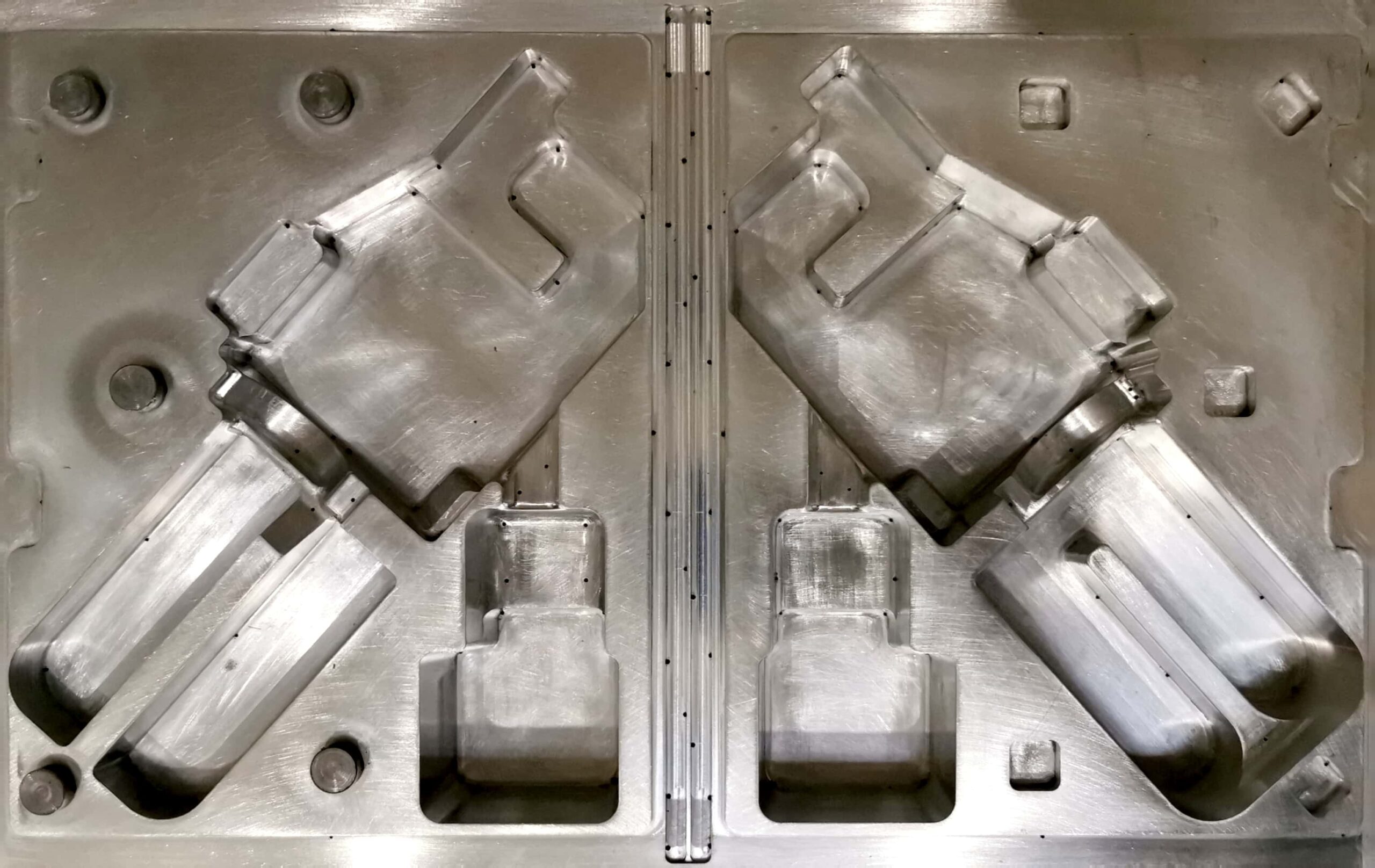

Injection molding

One of the most efficient and most widely used methods of producing simple as well as complex plastic products.

Example application:

- components of household appliances and consumer electronics

- enclosures

- bottle caps

- everyday use items

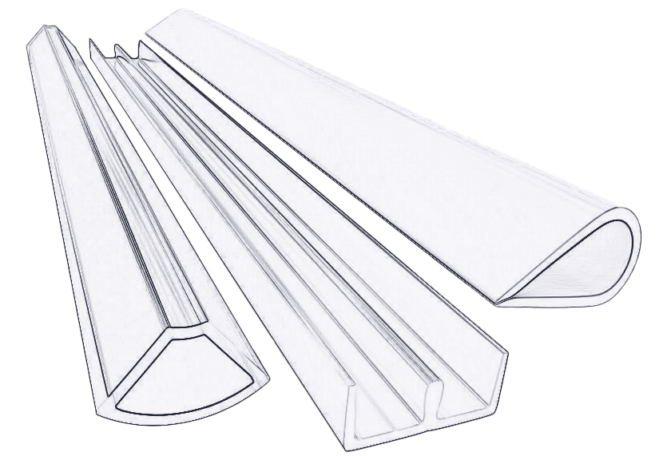

Extrusion

Ideal technology for large production runs of long components, such as profiles, pipes or gaskets.

Reduce plastic manufacturing costs

We make sure that the chosen production technology is

Optimal in terms of both technological and

and economic. Thanks to our experience and cooperation

with many industries, we know how to reduce production costs,

while ensuring the same quality of products.

Frequently Asked Questions

The cost of a mold, as a rule, ranges from a dozen to tens of thousands of zlotys. In the case of complex multi-cavity molds, it can be more than a hundred thousand zlotys. In some cases, instead of the whole mold, we can make replaceable inserts – then their cost will be from several to several thousand zlotys.

The cost of a mold, as a rule, ranges from a dozen to tens of thousands of zlotys. In the case of complex multi-cavity molds, it can be more than a hundred thousand zlotys. In some cases, instead of the whole mold, we can make replaceable inserts – then their cost will be from several to several thousand zlotys.

We can make a valuation based on:

- 3D model

- technical drawing

- physical object

- draft

- concept description.

We make products in as many as 4 production technologies, which enables us to offer our customers optimal plastic manufacturing solutions. These include:

- Thermoforming

- Rotational Casting (Rotomolding) Injection Molding

- Extrusion of Plastics